Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

The WP-AX series linear weigher is the perfect choice for precise product weighing. It features remote monitoring and tracking of products on the Internet, and adopts a stepless vibrator feeding system for accurate and efficient product weighing. This linear weigher is an ideal choice for a variety of industries, providing precise and reliable weighing solutions. It is also easy to use, making it a great choice for any business.

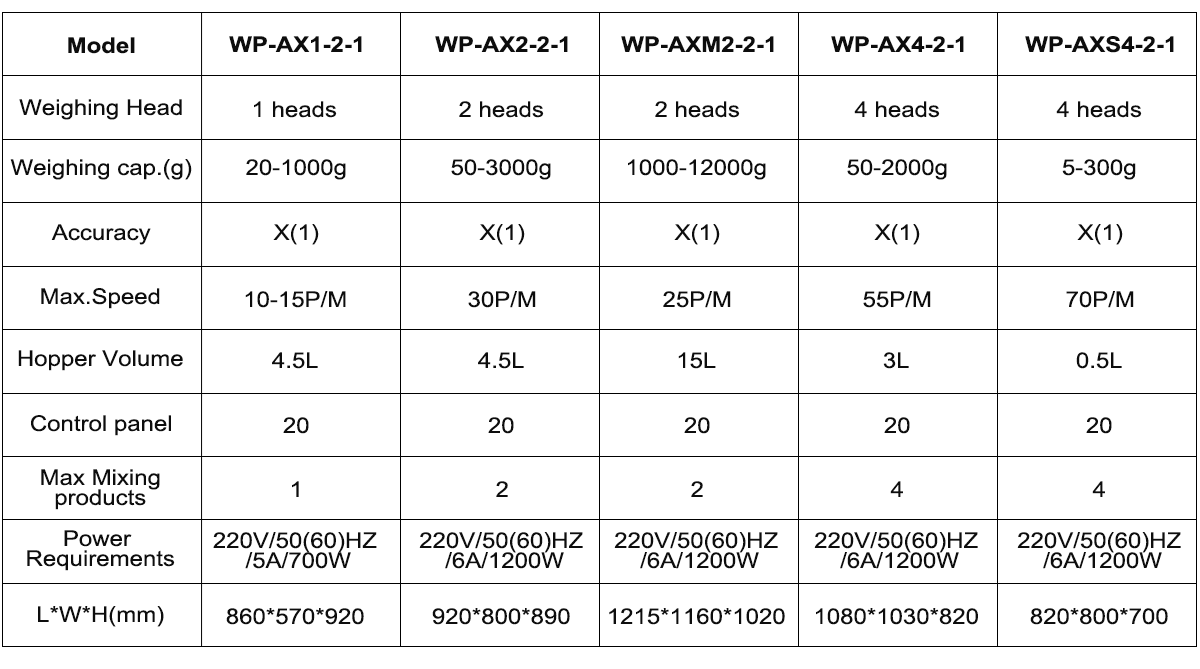

Product Specification:

Delivery Time: If the material is in stock, the delivery time is 20-25 days. If not, the delivery time is about 40-50 days.

The Technological Process: Design → Production → Assembling → Quality Testing → Packing → Loading → Shipping

Product Features

1. Remote monitoring and tracking of products on the Internet: With the WP-AX series linear weigher, you can remotely monitor and track products on the internet, giving you greater visibility and control over your production process. This feature allows you to keep track of production in real-time, identify and troubleshoot issues as they arise, and make data-driven decisions to optimize your workflow.

2. Multiple different products can be weighed at the same time to get the mixture packaging: The WP-AX series linear weigher is designed to handle multiple different products simultaneously, allowing you to create mixtures with high precision and accuracy. This means you can reduce the time and labor costs associated with weighing multiple components separately, while ensuring consistent quality and minimizing waste.

3. Adopt a stepless vibrator feeding system to make the product flow more fluently: The WP-AX series linear weigher uses a stepless vibrator feeding system that ensures smooth and consistent product flow. This feature helps prevent jams and blockages, reducing downtime and maximizing productivity. It also ensures that products are weighed accurately, helping to maintain quality standards and minimize waste.

Practical Cases and Applications

It is suitable for quantitative weighing of powdery and small granular materials such as sugar, salt, seeds, rice, sesame, monosodium glutamate, chicken essence, milk powder, coffee, seasoning powder, etc.

Our Professional Team & Skills

Our company has a modern standard factory, a visionary entrepreneurial team, a technically competent R&D echelon and strong after-sales technical service support.

We have been focusing on the R&D and manufacturing of packaging equipment for 10 years, absorbing a lot of advanced technology of foreign packaging machinery to improve and innovate, and aiming to become the benchmark and flag bearer in the industry.

At present, the technical department accounts for more than 20% of the company's headcount, and the annual investment in R&D reaches more than USD 500,000.